Willkommen bei Hivoduct

Dem Unternehmen für nachhaltige Stromübertragung, massgeschneiderte Produkte & bahnbrechende Technologie

Druckluftkabel sind die nachhaltige Lösung für effiziente und zukunftsorientierte Stromübertragung. Wir bieten innovative, umweltfreundliche Technologien für eine bessere Energiezukunft. Profitieren Sie von massgeschneiderten Lösungen, die Effizienz, Sicherheit und Nachhaltigkeit vereinen.

Unsere Vision

Druckluftkabel sind der neue Standard für die elektrische Energieübertragung

News

Bleiben Sie auf dem Laufenden! Hier finden Sie die neuesten Entwicklungen und innovativen Projekte rund um unsere Unternehmung

25. Mai 2025

25. Mai 2025Innovation braucht Systemkompetenz: Warum neue Wege im Stromnetzausbau entscheidend sind

Events

Werfen Sie einen Blick auf unsere bevorstehenden Veranstaltungen und sichern Sie sich Ihren Platz. Lassen Sie sich inspirieren und tauchen Sie ein in eine Welt voller Innovation und Erlebnisse. Wir freuen uns darauf, Sie persönlich begrüssen zu dürfen!

Möchten Sie vor Ort erleben, wie unsere hochwertigen Rohre produziert werden? Unsere Firmenbesichtigung bietet faszinierende Einblicke in die Prozesse, die hinter unseren erstklassigen Produkten stehen. Nutzen Sie die Gelegenheit, hinter die Kulissen zu schauen und unser Engagement für Qualität und Innovation hautnah mitzuerleben.

16. September 2025 bis 18. September 2025, Power Transmission & Distribution Messe in Köln

16. September 2025 bis 18. September 2025, Power Transmission & Distribution Messe in KölnPower Transmission & Distribution Messe

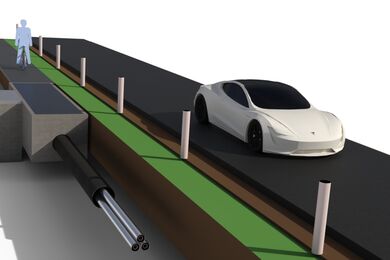

Hivoduct Druckluftkabel -Zukunftsweisende Technologie für eine nachhaltige Energieübertragung

Unsere innovative Druckluftkabel-Technologie setzt neue Massstäbe in der Energieinfrastruktur. Sie vereint höchste Effizienz, maximale Sicherheit und Umweltfreundlichkeit – perfekt für moderne, zukunftssichere Netzlösungen.

- Umweltfreundlich – Kein SF6, PFAS-frei, null Emissionen

- Maximale Effizienz – Geringe Verluste bei hohen Strömen, optimiert für höchste Leistungsfähigkeit

- Höchste Sicherheit – Geerdete, berührbare Gehäuse für zuverlässigen Schutz

- Platzsparendes Design – Kompakte Verlegung ohne Muffen, reduzierte Baukosten

- Perfekt für Tunnel & unterirdische Anwendungen – Keine Brandlast, ideal für enge Räume

- Flexibel & wartungsfreundlich – Schraubenlose, demontierbare Flansche für eine einfache Wartung

Hivoduct – Die beste Wahl für zukunftssichere Energieübertragung!

Gestalten Sie

Ihre perfekte Leitung!

Nutzen Sie unseren benutzerfreundlichen Online-Konfigurator und erstellen Sie Ihre massgeschneiderte Leitung – schnell, einfach und individuell.