Wall bushings

Technology for test labs

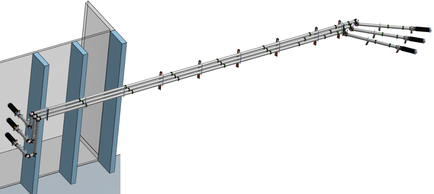

Pressurized air cables are ideal as wall bushings for switchgear, test laboratories, or industrial facilities with rated currents exceeding 1000 A.

We support you from engineering to on-site installation – with tailored solutions for your requirements.

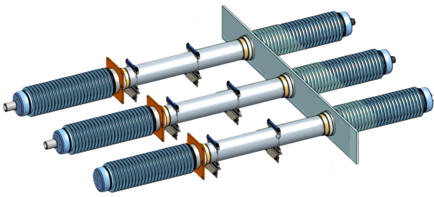

Pressurized air cables as wall bushings

Wall bushings are short high-voltage connections that pass through a wall from one side to the other. Pressurized air cables are ideal for this application, as their metallic casing can be connected to the building and grounding system while allowing very high nominal currents. The use of pressurized air as an insulating medium also reduces the installation weight.

Advantages of Using Pressurized Air Cables

High Current Capacity & Low Losses

Continuous currents of up to 5000 A can be transmitted with minimal heat losses.Integrated Grounding

The grounding is already integrated into the housing, saving space and costs without compromising safety.Optimal Fire Protection & High Arc Fault Resistance

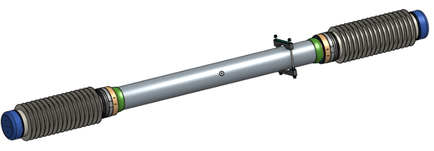

The metallic casing provides superior protection against fires and arc faults, minimizing the risk of damage and operational disruptions.Lightweight Construction

The air insulation within the connection and bushings reduces weight, decreasing the need for mounting or support structures.Optional Monitoring System

Pressurized air cables can be equipped with a pressure monitoring system that continuously tracks the pressure in each gas compartment.

For technical data details, please see here.

Cost comparison: Pressurized air cables vs. Wall bushings

Pressurized air cables are a cost-effective alternative to conventional wall bushings. The higher the nominal current, the more competitive pressurized air cables become

Wall bushing 145 kV, 3000 A

Wall bushing 72 kV, 2000 A

Wall bushing 145 kV, 3000 A with exit busducts

An efficient, space-saving, and environmentally friendly alternative to conventional cables, SF6 GIS, bushings, and GIL. Hivoduct pressurized air cables enable faster installation, reduced space requirements, and lower operating costs – ideal for test environments and individual applications.